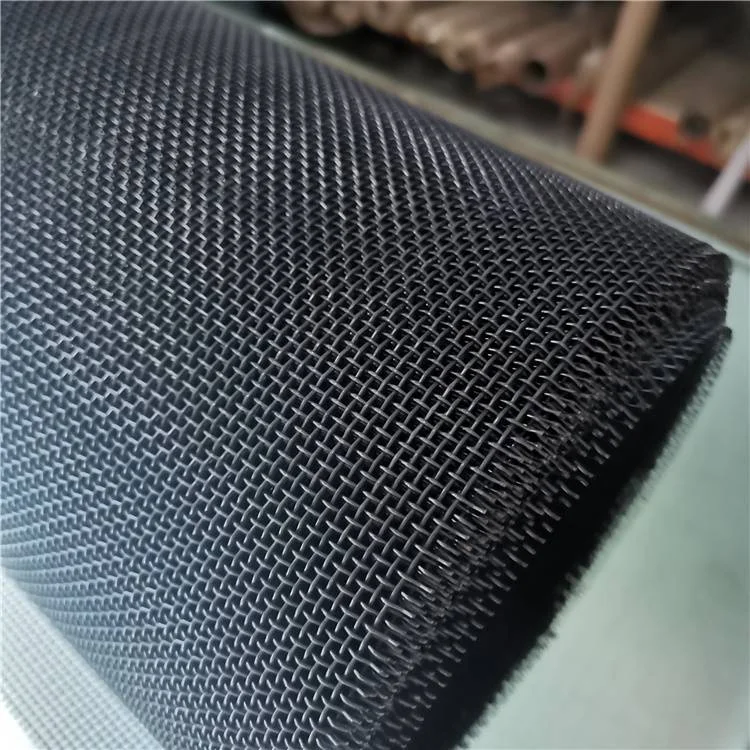

If you work with vacuum furnaces or high-temperature filtration, you already know what molybdenum wire mesh can do. To be honest, the last three years have made it even more relevant—semiconductor lines are getting hotter, hydrogen processing is trending, and reliability expectations are brutal. As a reporter-turned-buyer, I’ve seen specs creep upward while budgets… don’t. That’s where molybdenum wire mesh (often called “molybdenum mesh”) hits a sweet spot: melting point ≈2623°C, excellent dimensional stability, and a workhorse attitude in vacuum.

What’s changing in the industry

Furnace OEMs are shifting from graphite to refractory metal internals for longer life. Vacuum brazing and powder metallurgy are growing fast, while battery and hydrogen components demand cleaner, low-outgassing tooling. Surprisingly, many customers say they’re standardizing on molybdenum wire mesh for fixtures and screens because it holds shape after repeated 1100–1400°C cycles in H₂ or Ar. Caveat: avoid oxidizing atmospheres above ≈600°C—moly isn’t fond of them.

|

Parameter |

Typical value |

Notes |

|

Material |

Pure Mo ≥99.95% |

Moly or Mo alloy on request |

|

Mesh count |

4–200 mesh |

ISO 9044 / ASTM E2016 compliant |

|

Wire diameter |

0.03–1.0 mm |

Tighter tolerances available |

|

Weave types |

Plain, Twill, Dutch (dense) |

Square or rectangular openings |

|

Electrical resistivity |

≈5.3 μΩ·cm (20°C) |

Real-world use may vary |

|

CTE |

≈5.0 ×10⁻⁶/K |

Good thermal stability |

|

Melting point |

≈2623°C |

Refractory metal class |

Core specifications (typical)

From wire to woven: process and testing

Process flow (short version): vacuum-melted moly ingot → precision wire drawing → intermediate anneals → cleaned and lubricated → woven (plain/twill/Dutch) → degrease → vacuum anneal for stress relief → dimensional and surface check → packaging. Testing typically follows ASTM B387 for wire chemistry/mechanics, ISO 9044 and ASTM E2016 for mesh count, aperture, and diameter tolerances; optional low-outgassing per ASTM E595 if you’re going into UHV. Service life? In vacuum/H₂ at 1100–1400°C, many shops report 1000–3000 h before sag criteria are hit, but loading and fixture geometry matter a lot.

Where it’s used (and why)

· Vacuum furnace trays, screens, and shielding—stays flat through thermal cycling.

· Powder metallurgy sintering supports—clean, low contamination risk.

· Semiconductor diffusion and sputtering fixtures—stable, low outgassing.

· High-temp filtration in inert/hydrogen atmospheres—durable vs. stainless.

Many customers say molybdenum wire mesh cuts fixture replacement by a third versus 310/330 stainless when run hot in protective atmospheres.

Quick vendor snapshot (real-world buying factors)

|

Vendor |

Purity |

Mesh range |

Lead time |

Certs |

Notes |

|

Woven Filter Mesh |

≥99.95% |

4–200 |

2–4 weeks |

ISO 9001, RoHS |

Strong Dutch weave options |

|

Vendor A |

≥99.9% |

10–150 |

4–6 weeks |

ISO 9001 |

Lower MOQ, fewer weaves |

|

Vendor B |

≥99.95% |

6–180 |

Stock for common sizes |

ISO 9001, REACH |

Good for rush jobs |

Customization

Available customizations: mesh count and wire diameter pairing, sheet/roll sizing, weave (plain/twill/Dutch), edge trimming and framed panels, vacuum anneal level, flatness class, and inspection reports (CoC, 3.1 MTR). Ask for outgassing data if you’re running UHV.

Field results (quick cases)

· Vacuum brazing shop replaced 330SS screens with molybdenum wire mesh; after 9 months, tray sag reduced ≈28% and scrap dropped 12% on thin foils.

· Powder metallurgy line using Dutch-weave molybdenum mesh improved fines retention; cycle time held steady while cleaning intervals doubled.

Testing and certifications

Typical test data: tensile strength (room temp) 620–760 MPa; resistivity ≈5.3 μΩ·cm; dimensional tolerance per ISO 9044/ASTM E2016; chemistry per ASTM B387. Common certifications: ISO 9001, RoHS/REACH statements, material traceability to heat/lot, optional ASTM E595 outgassing reports. In practice, buyers also request flatness maps for large panels—worth it.

Bottom line: if heat, vacuum, and cleanliness are your world, molybdenum wire mesh is the safe, durable pick—just keep it out of oxidizers when it’s red hot.

References

1. ASTM E2016 – Standard Specification for Industrial Woven Wire Cloth

2. ISO 9044 – Industrial wire screens and woven wire cloth

3. ASTM B387 – Molybdenum and Molybdenum-Alloy Bar, Rod and Wire

4. MatWeb: Molybdenum, material properties (typical)

Anping Tengde Metal Wire Mesh Products Co., Ltd. Has been dedicated to the production and research and development of wire mesh products for 30 years. Leading Vibrating Screen It is a comprehensive department integrating production and processing, distribution and wholesale. Stainless steel mesh series, wire mesh products series, and filter elements and filter materials. Wire MeshWe can also produce various special-shaped net types and deep-processed net products according to customer needs and requirements. wire mesh suppliers All our products leaving the factory have undergone strict inspection to ensure that they are 100% qualified. Filtration Screens ManufacturerThe company adheres to the business philosophy of “technology leadership and quality victory”, and has nearly a hundred MID-to-senior level professional and technical personnel. wire mesh manufacturer We have maintained long-term and good cooperative relations with large domestic oil fields, coal mines, petroleum, machinery, chemical and other units, and have established good trade relations with more than 70 countries including the United States, Japan, Russia and Australia. Anping Tengde Metal Wire Mesh Products Co., Ltd.wire mesh screens suppliers Will continue to adhere to the tenet of “customer first, integrity-based”, and with the spirit of continuous innovation and win-win cooperation, forge ahead and challenge the future.wire mesh filter manufacturers|mesh wire suppliers