Nickel woven wire mesh is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of metal wire ropes and their products.

This article explores how Hebei Tengde Metal Wire Mesh Products Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Nickel woven wire mesh Overview

- Benefits & Use Cases of Nickel woven wire mesh in Manufacturing of metal wire ropes and their products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Nickel woven wire mesh from Hebei Tengde Metal Wire Mesh Products Co., Ltd

Nickel woven wire mesh Overview

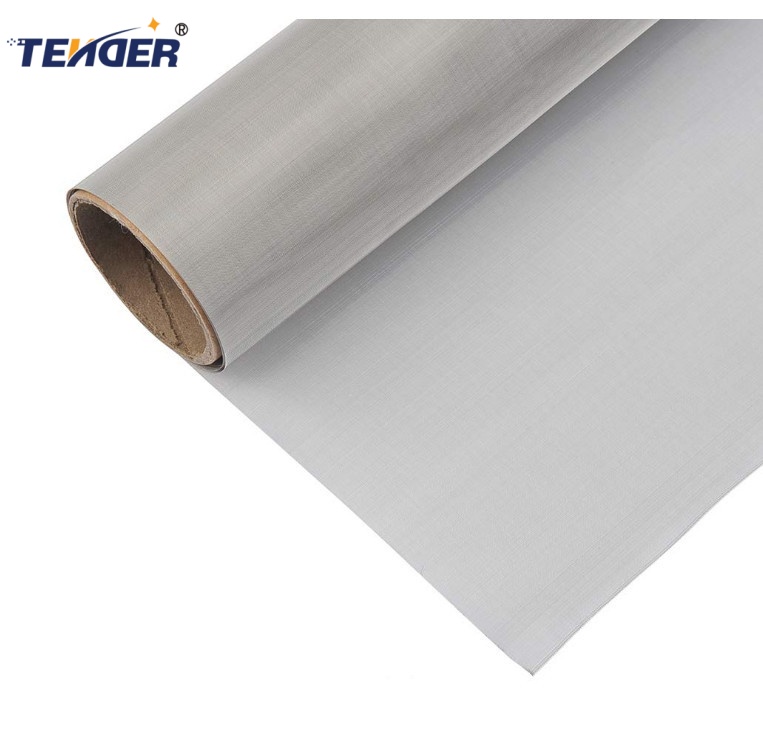

Nickel woven wire mesh is a precision-woven metallic cloth made from commercially pure nickel (commonly Nickel 200/201) designed for corrosion resistance, thermal stability, and reliable electrical conductivity. In the manufacturing ecosystem—especially within fabricated metal products and the manufacturing of metal wire ropes and their products—it serves as a robust medium for filtration, separation, shielding, and high-temperature support layers. Typical specifications include mesh counts from 2–400 mesh, wire diameters from 0.03–2.0 mm, and common weaves such as plain, twill, and Dutch. Standard widths up to 1.2 m are available, with custom slit widths, cut-to-size panels, and roll packaging options.

For metal wire rope production lines, nickel mesh offers dependable performance in aggressive media found in pickling, plating, and lubricant recirculation systems. Its stable microstructure withstands cyclic thermal loads during heat treatment and annealing supports. Hebei Tengde Metal Wire Mesh Products Co., Ltd manufactures nickel woven wire mesh with tight aperture control, uniform thickness, and consistent flatness, helping B2B operations maintain throughput and minimize unplanned downtime. With rigor in raw-material traceability and QC checkpoints across weaving and finishing, Tengde delivers a repeatable, audit-ready product suitable for high-spec industrial environments.

Benefits & Use Cases of Nickel woven wire mesh in Manufacturing of metal wire ropes and their products

Within wire drawing, stranding, and rope finishing, nickel woven wire mesh unlocks reliable performance where stainless steels may fall short. Typical applications include:

- Filtration and reclaim of wire drawing lubricants and coolants, reducing particulate load and extending fluid life.

- Anode baskets, catalytic guards, and plating filtration in nickel, copper, and specialty coating lines for wire and rope products.

- High-temperature support layers in continuous annealing and patenting operations, providing dimensional stability and scale resistance.

- Wiping and screening elements that prevent nozzle and die blockage, keeping line speeds stable and consistent.

- EMI/RFI shielding or grounding layers in specialized cable assemblies associated with rope-based hoisting and control systems.

Key advantages of nickel woven wire mesh include: excellent resistance to many alkaline environments and select acids, consistent electrical conductivity for current distribution, high-temperature tolerance, and precise, repeatable apertures for critical filtration. Hebei Tengde Metal Wire Mesh Products Co., Ltd pairs these material benefits with engineering support—advising on mesh count, wire diameter, and weave type—so decision makers can balance pressure drop, flow rates, and service life for each process cell. The result is a tailored component that integrates seamlessly into wire rope manufacturing lines and auxiliary finishing systems.

Cost, Maintenance & User Experience

From a total cost of ownership perspective, nickel woven wire mesh often outperforms lower-cost alternatives in harsh or high-temperature environments. While the initial unit price may be higher than conventional steel meshes, the extended service life, fewer changeovers, and reduced line outages typically improve ROI. In filtration and plating cells, stable performance can translate into lower scrap rates, cleaner surfaces, and fewer incidents of die or nozzle fouling—savings that ripple across the plant.

Maintenance is straightforward: depending on contamination type, users commonly deploy back-flushing, ultrasonic cleaning, or controlled chemical cleaning (alkaline or mild acid solutions, aligned with site safety protocols). Proper storage (dry, clean, chloride-aware) and periodic inspection of aperture integrity help maintain consistent performance. Customers in the fabricated metal products sector report improved fluid clarity and a measurable drop in unplanned maintenance events after switching to nickel mesh for critical stations.

Hebei Tengde supports lifecycle value with documentation packs, inspection records, and optional custom labeling for traceability. Consistent flatness and dimensional tolerances simplify installation into frames and housings, which reduces setup time and operator intervention during routine maintenance cycles.

Sustainability & Market Trends in manufacturing

Industrial buyers are aligning procurement with sustainability and compliance goals. Nickel woven wire mesh supports these objectives by delivering long service life—reducing replacement frequency and waste—and by being fully recyclable at end-of-life. As regulatory frameworks such as REACH and RoHS guide material selections, nickel mesh, when sourced responsibly, fits well into documented environmental and safety programs.

Market trends point to tighter filtration thresholds, higher-temperature processes, and greater digital traceability in wire rope production. This raises the bar for mesh uniformity, lot consistency, and documentation. Hebei Tengde Metal Wire Mesh Products Co., Ltd responds with process control, material certification on request, and packaging optimized for reduced damage and waste. By investing in quality systems and cleaner finishing methods, Tengde helps B2B stakeholders meet both productivity and ESG milestones—without compromising throughput or line stability.

Conclusion on Nickel woven wire mesh from Hebei Tengde Metal Wire Mesh Products Co., Ltd

For fabricated metal products and the manufacturing of metal wire ropes and their products, nickel woven wire mesh delivers durable, high-performance filtration, support, and conductive functionality. Hebei Tengde Metal Wire Mesh Products Co., Ltd combines material expertise with precision weaving and rigorous QC to provide reliable, specification-driven solutions that keep lines running and quality consistent.

Contact us: email: Darth@tender-wiremesh.com,Steelerindus@gmail.com

Visit our website: https://www.woven-filtermesh.com

Anping Tengde Metal Wire Mesh Products Co., Ltd. Has been dedicated to the production and research and development of wire mesh products for 30 years. Leading Vibrating Screen It is a comprehensive department integrating production and processing, distribution and wholesale. Stainless steel mesh series, wire mesh products series, and filter elements and filter materials. Wire MeshWe can also produce various special-shaped net types and deep-processed net products according to customer needs and requirements. wire mesh suppliers All our products leaving the factory have undergone strict inspection to ensure that they are 100% qualified. Filtration Screens ManufacturerThe company adheres to the business philosophy of “technology leadership and quality victory”, and has nearly a hundred MID-to-senior level professional and technical personnel. wire mesh manufacturer We have maintained long-term and good cooperative relations with large domestic oil fields, coal mines, petroleum, machinery, chemical and other units, and have established good trade relations with more than 70 countries including the United States, Japan, Russia and Australia. Anping Tengde Metal Wire Mesh Products Co., Ltd.wire mesh screens suppliers Will continue to adhere to the tenet of “customer first, integrity-based”, and with the spirit of continuous innovation and win-win cooperation, forge ahead and challenge the future.wire mesh filter manufacturers|mesh wire suppliers