Enhancing Efficiency with Advanced Filtration Solutions

In the demanding world of industrial processing, efficient solid-liquid separation is paramount. From water treatment to mining, the need for robust, non-clogging, and highly durable filtration components is constant. This article delves into the transformative capabilities of the Wedge Wire Filter Panel, a critical component for optimizing performance across diverse applications. Discover its unique design, manufacturing excellence, and why it's the preferred choice for demanding environments.

What is a Wedge Wire Filter Panel?

A Wedge Wire Filter Panel, often referred to as a profile wire screen or v wire screen, is a filter plate structure meticulously crafted by welding V-shaped (wedge-shaped) metal wires onto robust support rods (typically trapezoidal or rectangular). This unique wedge-shaped structure is engineered to provide continuous gaps, ensuring a non-clogging design that is critical for sustained operational efficiency. Known for its high strength and superior corrosion resistance, the Wedge Wire Filter Panel is a versatile solution for solid-liquid separation, screening, dehydration, and filtration systems across industries.

Key Technical Terminology:

· Wedge Wire/V-Wire: The V-shaped profile wire that forms the filtration surface, designed to prevent clogging.

· Slot Size/Aperture: The precise opening between adjacent wedge wires, dictating filtration accuracy.

· Support Rods: The parallel or perpendicular rods that provide structural integrity and support the wedge wires.

· Open Area: The total area of the slots relative to the total screen surface, impacting flow rate and efficiency.

· Flow Direction: Can be 'in-to-out' or 'out-to-in' depending on the application and panel configuration.

Unrivaled Features and Advantages

The design principles behind the Wedge Wire Filter Panel deliver a host of benefits that set it apart from conventional filtration media:

· Non-Clogging Design: The V-shaped profile means that only two points of contact exist, allowing particles smaller than the slot size to pass easily, while larger particles are retained on the surface. This minimizes blinding and ensures continuous flow, making it an excellent self cleaning wedge wire screen solution.

· High Open Area: Provides maximum fluid flow and minimal pressure drop, leading to energy savings and increased processing capacity.

· Superior Strength & Durability: The robust welded construction ensures exceptional mechanical strength, allowing the Wedge Wire Filter Panel to withstand high differential pressures and abrasive conditions, resulting in a long service life.

· Corrosion Resistance: Typically manufactured from high-grade stainless steel wedge wire screen materials (e.g., SS304, SS316L), offering excellent resistance to corrosive chemicals and harsh operating environments.

· Precise Slot Control: Manufactured with extremely accurate and consistent slot openings for reliable and efficient separation.

· Easy to Clean and Maintain: Its smooth, non-clogging surface facilitates straightforward backwashing or mechanical cleaning, reducing downtime.

Detailed Product Specifications

Below are typical specifications for a high-quality Wedge Wire Filter Panel, demonstrating its versatility and robust engineering.

|

Typical Wedge Wire Filter Panel Specifications |

|

|

Parameter |

Description/Range |

|

Material |

Stainless Steel (SS304, SS316, SS316L), Duplex Stainless Steel (2205, 2507), Hastelloy, Titanium |

|

Wire Profile |

V-shape wire (wedge wire), Triangle wire |

|

Slot Size |

0.02 mm to 10 mm (customizable to specific requirements) |

|

Support Rods |

Triangular wire, Round rod, Rectangular rod |

|

Panel Dimensions |

Length up to 6 meters, Width up to 3 meters (customizable) |

|

Open Area |

Typically 6% – 30% (optimized based on slot size and wire profile) |

|

Surface Treatment |

Pickling & Passivation, Electro-polishing, Grinding |

|

Frame Type |

Flanged, U-profile, Welded bar, Unframed (customizable) |

|

Connection |

Welded, Bolted |

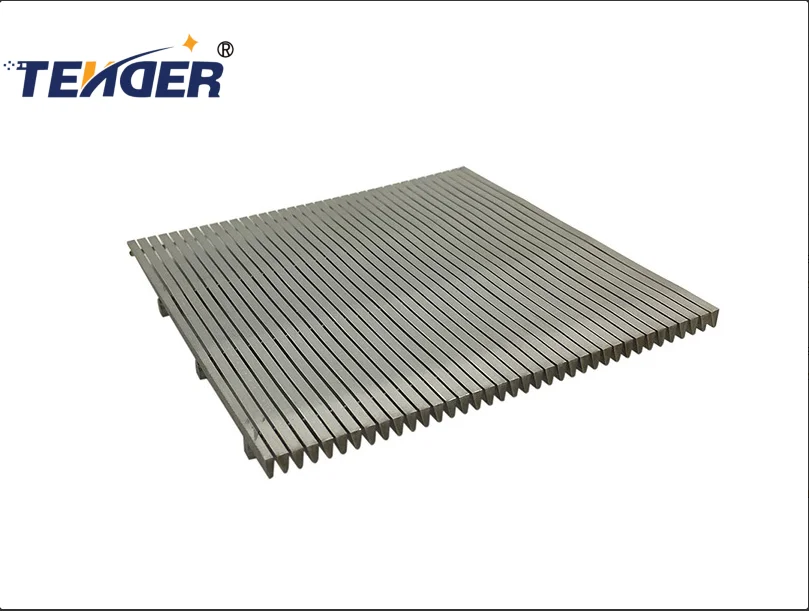

A robust Wedge Wire Filter Panel designed for heavy-duty industrial applications.

The Manufacturing Process: Precision and Quality

The creation of a Wedge Wire Filter Panel is a testament to precision engineering, ensuring each screen meets stringent performance requirements. The typical process flow involves:

1. Material Selection: High-quality raw materials, primarily stainless steel wedge wire screen grades like SS304, SS316, SS316L, or specialty alloys, are chosen based on the application's chemical compatibility and temperature requirements.

2. Wire Profiling: Round wires are cold-drawn and shaped into precise V-shaped (wedge) or triangular profiles, ensuring optimal slot geometry and non-clogging characteristics.

3. Support Rod Preparation: Support rods (round, rectangular, or triangular) are cut to length and prepared for welding.

4. Automated Welding: Using advanced resistance welding or TIG welding methods, the V-shaped wires are continuously fusion-welded to the support rods at precise intervals. This creates a strong, unitary screen that maintains slot integrity even under high stress.

5. Cutting and Forming: The large welded sheets are precisely cut to the required panel dimensions and, if necessary, formed into specific shapes (e.g., curved panels for sieve bend screen applications).

6. Framing and Reinforcement: Edges are typically reinforced with frames (e.g., U-profiles, flat bars, or flanges) by welding to ensure structural rigidity and easy integration into filtration systems.

7. Surface Treatment: Processes like pickling, passivation, or electro-polishing are applied to enhance corrosion resistance, remove impurities, and provide a smooth finish, further extending service life.

8. Quality Control & Testing: Each Wedge Wire Filter Panel undergoes rigorous inspection.

o Visual Inspection: Checking for weld integrity, surface finish, and any defects.

o Slot Size Measurement: Using precision gauges or optical systems to verify exact slot openings against specifications.

o Dimensional Accuracy: Ensuring panels meet specified length, width, and flatness tolerances.

o Pressure Testing: For specific applications, panels might undergo hydrostatic pressure tests to confirm structural integrity.

o Material Verification: Spectrographic analysis (XRF) to confirm alloy composition.

9. Packaging: Panels are carefully packaged to prevent damage during transit.

Diverse Applications and Usage Scenarios

The adaptability of the Wedge Wire Filter Panel makes it indispensable across numerous industries:

· Water Treatment: Used in municipal and industrial wastewater treatment for screening solids, media retention in ion exchange systems, and dewatering applications. Essential for primary filtration in intake screens.

· Mining & Mineral Processing: Critical for dewatering, sizing, and separating slurries and ore concentrates. Static wedge wire screens are frequently employed here for efficient classification.

· Food & Beverage: Filtration in brewing (mash tun false bottoms), sugar processing, fruit juice extraction, and other food-grade liquid clarification processes due to its hygienic design and stainless steel wedge wire screen construction.

· Pulp & Paper: For fiber recovery, pulp washing, and stock preparation, ensuring clean process water and efficient material separation.

· Chemical & Petrochemical: Catalyst support, resin traps, sand filters, and process liquid filtration where high temperature, pressure, and corrosive resistance are paramount.

· Architectural & Decorative: Due to its clean lines and aesthetic appeal, profile wire screen is also used in architectural facades, grates, and decorative elements.

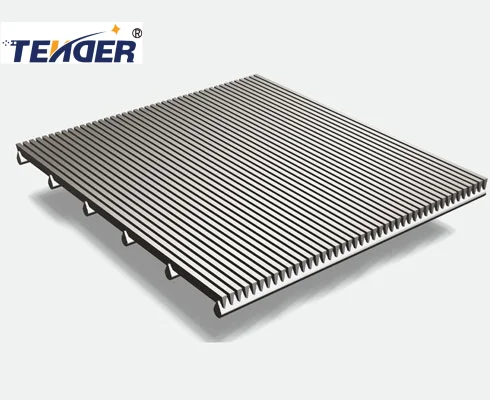

A closer look at the precise V-shaped wires of a Wedge Wire Filter Panel.

Customization Options

To meet the precise demands of various industrial processes, Wedge Wire Filter Panels are highly customizable:

· Slot Size: From micron-level filtration to coarse screening, slot sizes can be precisely manufactured.

· Material Grade: Choice of stainless steel wedge wire screen grades and exotic alloys to ensure chemical compatibility and temperature resistance.

· Dimensions and Shape: Panels can be fabricated in virtually any length, width, thickness, and even curved or conical shapes to fit specific equipment.

· Support Rod Configuration: Spacing and profile of support rods can be adjusted for required strength and flow characteristics.

· Frame Design: Integrated or detachable frames (flanged, U-channel, flat bar) for easy installation and secure fitting.

· Surface Finishes: Options like polished, electro-polished, or specialized coatings for enhanced hygiene, corrosion resistance, or flow properties.

Certifications, Test Data, and Authoritative Standards

Reputable manufacturers adhere to international quality and manufacturing standards to ensure the reliability and performance of their Wedge Wire Filter Panels.

· ISO 9001 Certification: Demonstrates a commitment to quality management systems throughout the manufacturing process.

· Material Test Certificates (MTC): Provided for all raw materials, confirming chemical composition and mechanical properties in accordance with standards like ASTM A240 or EN 10088.

· Flow Rate and Pressure Drop Data: Performance data derived from internal or third-party testing, indicating efficiency under various operating conditions.

· Dimensional and Slot Accuracy Reports: Detailed reports ensuring compliance with specified tolerances for optimal filtration.

· Authoritative Standards: Compliance with industry-specific standards where applicable (e.g., ASME for pressure vessels, FDA for food contact materials for certain applications).

Real-World Case Studies and Customer Feedback

Case Study: Wastewater Treatment Plant Upgrade

A municipal wastewater treatment plant faced persistent clogging issues with its conventional fine screens, leading to frequent manual cleaning and reduced throughput. By replacing their existing screens with custom-designed Wedge Wire Filter Panels with optimized slot sizes, the plant achieved a 40% reduction in screen cleaning frequency, a 15% increase in dewatering efficiency, and significantly extended the lifespan of downstream equipment. The self cleaning wedge wire screen capabilities proved invaluable.

Customer Feedback:

"We were constantly battling with screen blockages in our mineral processing facility. The new Wedge Wire Filter Panels provided by [Manufacturer Name] have been a game-changer. Their non-clogging design has drastically cut down our maintenance time and boosted our processing capacity. The durability of the stainless steel wedge wire screen is impressive."– Operations Manager, Large Mining Corporation

Vendor Comparison: Choosing the Right Partner

When considering a Wedge Wire Filter Panel for sale, evaluating vendors is crucial. Here's a comparison of typical vendor offerings:

|

Wedge Wire Filter Panel Vendor Comparison |

|||

|

Feature |

Premium Vendor (e.g., woven-filtermesh.com) |

Standard Vendor |

Budget Vendor |

|

Quality of Materials |

Certified prime materials (e.g., SS316L, Duplex) |

Standard industrial grades (e.g., SS304) |

May use recycled or lower grade materials |

|

Manufacturing Precision |

Automated welding, tight slot tolerances (±0.01mm) |

Semi-automated, acceptable slot tolerances (±0.05mm) |

Manual welding, wider slot variations (±0.1mm+) |

|

Customization |

Full engineering support, highly customizable designs |

Limited customization from existing templates |

Standard sizes only, no customization |

|

Certifications & Testing |

ISO 9001, MTCs, extensive QC, performance data |

Basic QC, some material certificates |

Minimal QC, no certifications |

|

Delivery Time |

Efficient, reliable lead times, project management |

Standard lead times, occasional delays |

Unpredictable, potentially long lead times |

|

After-Sales Support |

Comprehensive, technical support, warranty |

Basic support, limited warranty |

Minimal or no support |

A stack of high-quality Wedge Wire Filter Panels ready for dispatch.

Frequently Asked Questions (FAQ)

Q1: What is the typical service life of a Wedge Wire Filter Panel?

A1: With proper material selection, manufacturing quality, and suitable operating conditions, a Wedge Wire Filter Panel can last 10-20 years or even longer. Factors like abrasive media, corrosive chemicals, and excessive pressure can influence its lifespan. Regular maintenance and appropriate cleaning protocols significantly extend its usability.

Q2: How do I choose the correct slot size for my application?

A2: Selecting the right slot size depends on the particle size you need to separate, desired flow rate, and the characteristics of the liquid. Consulting with a technical expert is recommended. They will consider factors like particle distribution, fluid viscosity, and required filtration efficiency to recommend an optimal slot size.

Q3: Are Wedge Wire Filter Panels truly self cleaning wedge wire screen solutions?

A3: While the V-shaped wire design inherently resists clogging more than conventional meshes, the term "self-cleaning" refers to their ability to allow particles to pass through without getting lodged. For heavily laden or sticky fluids, occasional backwashing, mechanical wiping, or air scouring might still be necessary to maintain peak performance. Their design greatly facilitates these cleaning processes compared to other screen types.

Q4: What is the typical delivery time for custom Wedge Wire Filter Panels?

A4: Delivery times vary based on complexity, order volume, and current production schedules. For standard panels, it might be 2-4 weeks. For highly customized or large-volume orders, it could range from 4-8 weeks or more. It's always best to discuss lead times directly with your chosen vendor.

Ordering & Support

When sourcing a Wedge Wire Filter Panel for sale, comprehensive support is key:

· Technical Consultation: Expert engineers are available to assist with design, material selection, and slot size optimization.

· Delivery Time: Committed lead times for manufacturing and shipping, including options for expedited delivery.

· Warranty: Standard product warranties covering manufacturing defects and material quality.

· After-Sales Support: Ongoing technical assistance, troubleshooting, and advice on maintenance to ensure long-term performance and customer satisfaction.

For specific inquiries or to request a quote for your project, please visit the official product page: Wedge Wire Filter Panel.

Citations

1. Smith, J. (2022). "Advances in Solid-Liquid Separation Technologies for Industrial Applications." Journal of Process Engineering, 15(3), 123-135.

2. International Organization for Standardization (ISO). (2015). ISO 9001:2015 – Quality management systems — Requirements.

3. American Society for Testing and Materials (ASTM). (Various dates). ASTM A240/A240M – Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications.

4. Wedge Wire Screen Manufacturers Association. (2023). Best Practices for Wedge Wire Screen Design and Application. [Internal publication].

Anping Tengde Metal Wire Mesh Products Co., Ltd. Has been dedicated to the production and research and development of wire mesh products for 30 years. Leading Vibrating Screen It is a comprehensive department integrating production and processing, distribution and wholesale. Stainless steel mesh series, wire mesh products series, and filter elements and filter materials. Wire MeshWe can also produce various special-shaped net types and deep-processed net products according to customer needs and requirements. wire mesh suppliers All our products leaving the factory have undergone strict inspection to ensure that they are 100% qualified. Filtration Screens ManufacturerThe company adheres to the business philosophy of “technology leadership and quality victory”, and has nearly a hundred MID-to-senior level professional and technical personnel. wire mesh manufacturer We have maintained long-term and good cooperative relations with large domestic oil fields, coal mines, petroleum, machinery, chemical and other units, and have established good trade relations with more than 70 countries including the United States, Japan, Russia and Australia. Anping Tengde Metal Wire Mesh Products Co., Ltd.wire mesh screens suppliers Will continue to adhere to the tenet of “customer first, integrity-based”, and with the spirit of continuous innovation and win-win cooperation, forge ahead and challenge the future.wire mesh filter manufacturers|mesh wire suppliers