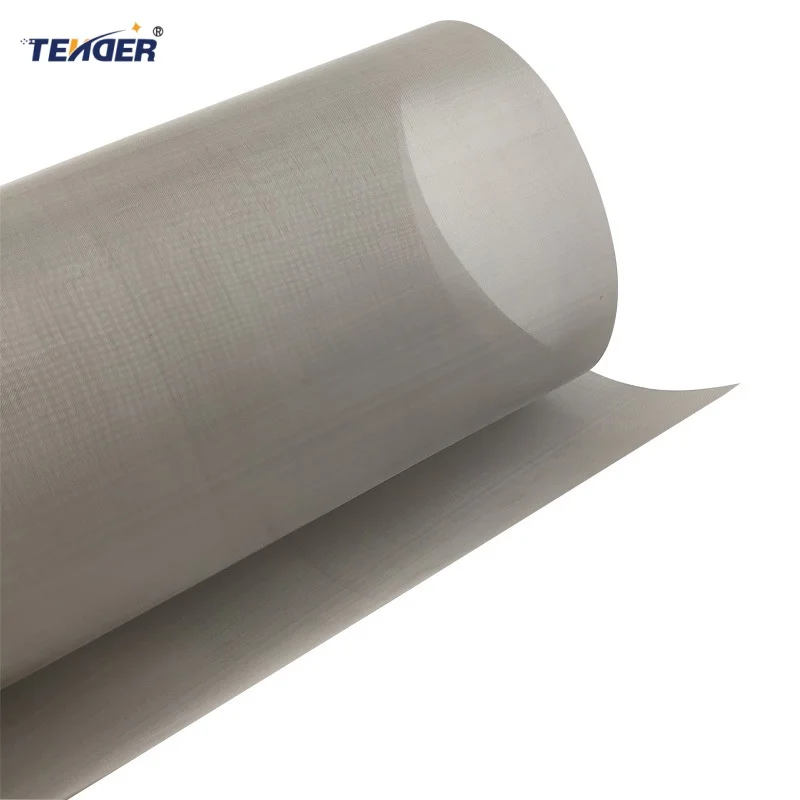

You know, sometimes the simplest things are the most profound. Take metal steel mesh, for instance. It might sound mundane, perhaps just a fence or a sieve. But if you're actually paying attention to industrial design, manufacturing, or even advanced scientific research, you'll quickly realize it's a critical component, performing tasks far more complex than meets the eye. From filtration to reinforcement, it's absolutely everywhere.

More Than Just Wires: Industry Trends & Evolution

The world of metal steel mesh has seen quite an evolution, actually. We've moved far beyond basic woven wire. Today's industry trends lean heavily towards specialized alloys, finer weaves, and engineered solutions for extreme conditions. Think about it: increasing demands for higher filtration efficiency, better corrosion resistance, and incredible strength-to-weight ratios in ever more aggressive environments. Manufacturers are pushing boundaries, leveraging new materials and advanced weaving techniques to meet these challenges. It's truly fascinating.

Materials, Methods, and the Magic of Manufacturing

The journey of metal steel mesh begins, quite obviously, with the raw material. While stainless steel wire & mesh (think 304, 316L) remains a workhorse, we're seeing a surge in demand for exotic alloys. Materials like Hastelloy, Inconel, Monel, and titanium are becoming commonplace, chosen for their specific advantages in highly corrosive or high-temperature applications. The manufacturing process typically involves precision weaving, where wires are interlaced at specific angles and tensions to create various mesh types – plain weave, twilled weave, Dutch weave, and so on. Each offers distinct filtration characteristics and mechanical properties. To be honest, the precision involved in weaving some of the finer meshes is truly astounding.

A Closer Look: Hastelloy Woven Wire Mesh

Let's talk about one particular high-performance variant: Hastelloy mesh. It’s a prime example of advanced metal mesh stainless steel solutions. Made from Hastelloy alloy – a family of nickel-molybdenum-chromium superalloys – it boasts exceptional resistance to harsh chemicals, strong oxidizing agents, and high temperatures. This makes it indispensable in sectors where other materials simply wouldn't survive.

Here’s a quick glance at some typical specifications for a high-quality Hastelloy Woven Wire Mesh:

|

Specification |

Details (Hastelloy C-276) |

|

Material Composition |

Nickel (≈57%), Molybdenum (≈16%), Chromium (≈15.5%), Iron (≈5%), Tungsten (≈4%), Cobalt (≈2.5%) |

|

Weave Type |

Plain, Twilled, Dutch Weave (customizable) |

|

Mesh Count Range |

2 to 400 mesh per inch (real-world use may vary based on wire diameter) |

|

Wire Diameter |

0.025mm to 2mm (customizable) |

|

Operating Temperature |

Up to ≈1093°C (2000°F) in non-oxidizing environments |

|

Corrosion Resistance |

Excellent in reducing and oxidizing acids, pitting, crevice corrosion, stress-corrosion cracking |

|

Standard Roll Width/Length |

0.914m-1.22m width, 30m length (often customized) |

Application Scenarios & Advantages: Where It Shines

The usage scenarios for high-performance stainless steel filter mesh and other exotic metal meshes are incredibly diverse. Industries like chemical processing, marine engineering, aerospace, pharmaceutical, and even nuclear power rely on these materials. For instance, in chemical plants, Hastelloy mesh is used for reaction vessels, heat exchangers, and filter screens where exposure to strong acids or chlorides would quickly degrade other metals. In aerospace, lightweight yet strong mesh can be found in engine components or fuel filters. Its advantages are clear: superior corrosion resistance means longer service life, reduced maintenance, and ultimately, enhanced safety and cost-effectiveness. Many customers say it's simply indispensable for their most demanding applications.

Choosing Your Partner: Vendor Comparison & Customization

When it comes to sourcing steel metal mesh, vendor selection is crucial. It’s not just about price, you know. Quality, reliability, and the ability to customize are paramount. Look for suppliers who adhere to authoritative standards like ASTM or ISO, and can provide comprehensive test data and material certifications. Customization, actually, is often the deciding factor. Whether it's a specific mesh count, wire diameter, unique alloy blend, or a custom fabrication, a good vendor can tailor solutions precisely to your project's needs.

|

Aspect |

Specialized Vendor |

General Supplier |

|

Material Range |

Broad, including exotic alloys (Hastelloy, Inconel) |

Mainly common stainless steels |

|

Customization |

High: custom weaves, sizes, fabrications, material blends |

Limited to standard dimensions/meshes |

|

Technical Support |

In-depth, material science expertise |

Basic product information only |

|

Certifications/QA |

Strict, often with traceable batch data and MTRs |

May vary, sometimes less rigorous |

|

Lead Times |

Can be longer for custom orders, but reliable |

Faster for standard items, slower for anything unique |

|

Pricing |

Generally higher due to specialized materials/expertise |

More competitive for bulk, standard items |

The Bottom Line: Durability, Reliability, and Innovation

Ultimately, whether you're dealing with standard metal steel mesh or advanced Hastelloy woven wire, the core value proposition is about durability and reliability. The service life of properly selected and manufactured mesh can be incredibly long, even in harsh conditions, minimizing downtime and replacement costs. It seems that as industries continue to demand more from their materials, the innovation in metal mesh will only accelerate. From improved weaving techniques to the development of new, even more resilient alloys, the future of this seemingly simple product is surprisingly dynamic.

Authoritative Citations

1. ASTM International. (2023). ASTM E2016/E2016M-23, Standard Guide for Industrial Woven Wire Cloth.

2. Special Metals Corporation. (2022). INCONEL alloys. Retrieved from specialmetals.com

3. Haynes International. (2023). HAYNES® 276 alloy. Retrieved from haynesintl.com

Anping Tengde Metal Wire Mesh Products Co., Ltd. Has been dedicated to the production and research and development of wire mesh products for 30 years. Leading Vibrating Screen It is a comprehensive department integrating production and processing, distribution and wholesale. Stainless steel mesh series, wire mesh products series, and filter elements and filter materials. Wire MeshWe can also produce various special-shaped net types and deep-processed net products according to customer needs and requirements. wire mesh suppliers All our products leaving the factory have undergone strict inspection to ensure that they are 100% qualified. Filtration Screens ManufacturerThe company adheres to the business philosophy of “technology leadership and quality victory”, and has nearly a hundred MID-to-senior level professional and technical personnel. wire mesh manufacturer We have maintained long-term and good cooperative relations with large domestic oil fields, coal mines, petroleum, machinery, chemical and other units, and have established good trade relations with more than 70 countries including the United States, Japan, Russia and Australia. Anping Tengde Metal Wire Mesh Products Co., Ltd.wire mesh screens suppliers Will continue to adhere to the tenet of “customer first, integrity-based”, and with the spirit of continuous innovation and win-win cooperation, forge ahead and challenge the future.wire mesh filter manufacturers|mesh wire suppliers