You know, it's funny how some materials are just everywhere but rarely get the recognition they deserve. Take metal steel mesh, for instance. From your humble kitchen sieve to the intricate filters in a massive chemical plant, it's a true workhorse. But what happens when 'standard' just isn't good enough? That's when we start talking about specialized alloys, like Hastelloy, and that, to be honest, is where things get really interesting.

The Evolution of Metal Mesh: From Simple Screening to High-Tech Filtration

For decades, a good sturdy metal mesh stainless steel was the go-to. And don't get me wrong, stainless steel still holds its own in countless applications. But industry trends are pushing boundaries. We're seeing demand for materials that can withstand increasingly aggressive environments – think extreme temperatures, highly corrosive chemicals, and incredible pressures. This isn't just about filtering particles anymore; it's about safeguarding critical processes and extending equipment life.

Introducing Hastelloy Woven Wire Mesh: A Game Changer

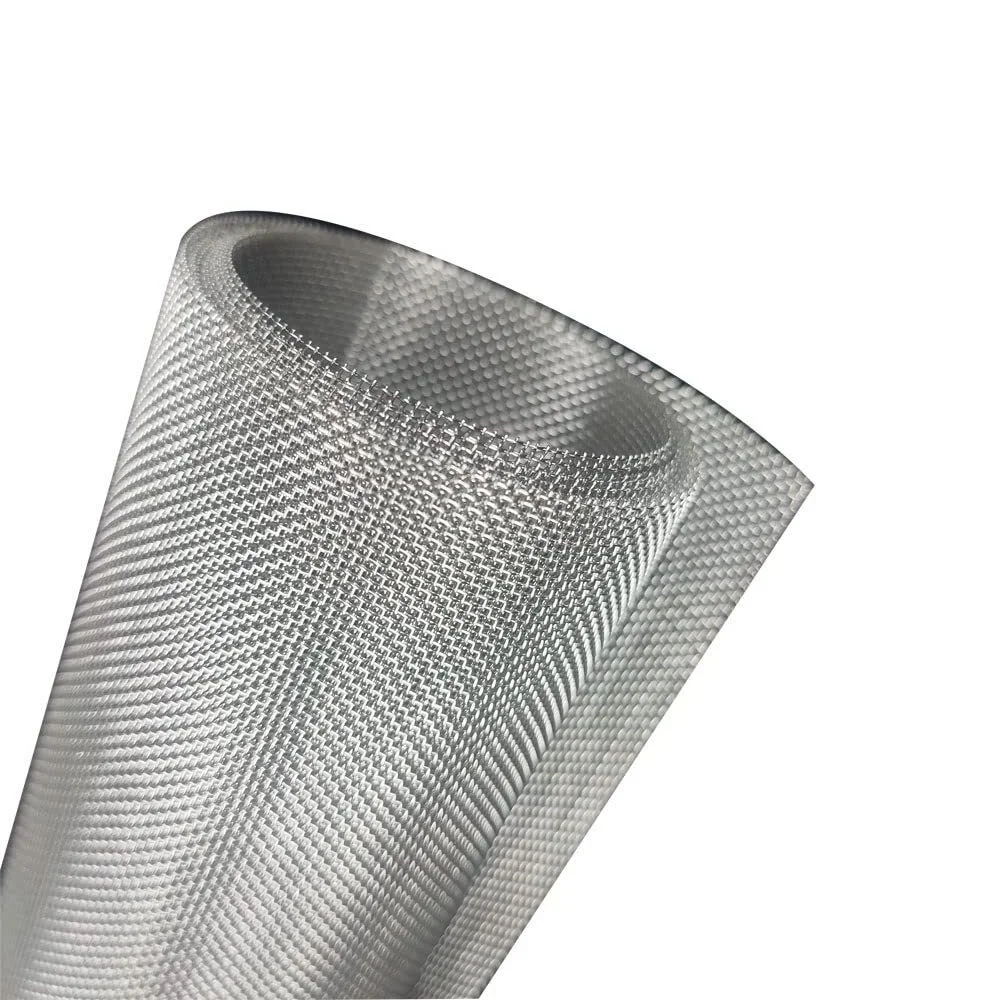

When standard stainless steel wire & mesh can't cut it, that's where Hastelloy woven wire mesh steps in. This isn't your average `steel metal mesh`. Hastelloy is a family of superalloys, primarily composed of nickel, molybdenum, and often iron and cobalt. The magic really lies in its exceptional corrosion resistance, even in incredibly harsh acidic or alkaline conditions, and its remarkable high-temperature strength. It's truly built for environments where failure isn't an option, and frankly, many customers I've spoken with swear by it.

Technical Deep Dive: What Makes Hastelloy So Special?

Let's get a bit technical, shall we? The production process for Hastelloy mesh is quite precise. It starts with carefully alloyed wires, which are then woven using specialized machinery – typically plain weave, twilled weave, or even Dutch weave for finer filtration needs. These methods are chosen based on the desired pore size, flow rate, and mechanical strength. Quality control is rigorous; we're talking about extensive testing for tensile strength, aperture size, and material composition to meet standards like ASTM or ISO.

Typical Hastelloy Woven Wire Mesh Specifications:

|

Characteristic |

Details |

|

Material Grade |

Hastelloy C-276, C-22, B-2 (most common) |

|

Wire Diameter Range |

0.02mm to 2.0mm (real-world use may vary) |

|

Mesh Count |

1 to 300 Mesh (or finer for specific Dutch weaves) |

|

Weave Type |

Plain, Twill, Dutch (Plain/Twill preferred for strength) |

|

Tensile Strength |

Impressive, significantly higher than most stainless |

|

Operating Temp. |

Up to ≈1000°C (depending on specific grade & environment) |

|

Corrosion Resistance |

Excellent in acids, chlorine, reducing/oxidizing media |

Applications & Real-World Impact

Where do you find this premium metal steel mesh? Well, it's pretty much indispensable in industries where failure simply isn't an option. Chemical engineering is a big one, particularly in reactors, heat exchangers, and distillation columns. Marine engineering benefits hugely from its resistance to saltwater corrosion. And aerospace? Absolutely, for components that need to withstand extreme thermal cycling and corrosive fuels. I've even seen it in waste treatment facilities, surprisingly, where aggressive chemicals are used to process effluents. The service life, when properly selected and maintained, is truly exceptional, often outlasting cheaper alternatives by years, if not decades.

Navigating the Vendor Landscape & Customization

When it comes to sourcing specialized metal steel mesh like Hastelloy, it's not just about price. Quality, certification, and customization capabilities are paramount. Many manufacturers offer bespoke solutions – different weave patterns, specific mesh counts, custom widths, and even fabricated parts like baskets or strainers. Always ask about their testing standards and certifications (e.g., ISO 9001). Customer feedback often highlights reliability and consistency as key differentiators.

Vendor Comparison (Illustrative):

|

Feature |

Vendor A (Specialist) |

Vendor B (Generalist) |

|

Hastelloy Expertise |

High, deep material knowledge |

Moderate, part of broader offering |

|

Customization Options |

Extensive, design consultation |

Limited to standard sizes/weaves |

|

Certifications |

ISO 9001, Material Test Reports |

Basic material certificates |

|

Lead Time (Custom) |

Around 4-6 weeks |

≈ 8-10 weeks (longer) |

|

Technical Support |

Excellent, application engineers |

Standard customer service |

The Bottom Line: Investing in Performance

Ultimately, choosing the right stainless steel filter mesh – or in this case, a high-performance Hastelloy mesh – isn't just a procurement decision. It's an investment in the reliability, safety, and longevity of your operations. While the upfront cost might be higher than traditional stainless steel, the long-term benefits in reduced downtime, minimized maintenance, and enhanced process efficiency often far outweigh the initial outlay. It seems that for truly demanding applications, the advantages of materials like Hastelloy are simply undeniable.

Authoritative Citations:

1. ASTM International. "Standard Specification for Nickel-Molybdenum-Chromium-Iron Alloys (UNS N10276, UNS N06022, UNS N06455, UNS N06985, UNS R20033) for Chemical Process Service." ASTM B575.

2. Special Metals Corporation. "Hastelloy® C-276 Alloy." Technical Data Sheet.

3. International Organization for Standardization (ISO). "ISO 9001:2015 – Quality management systems — Requirements."

Anping Tengde Metal Wire Mesh Products Co., Ltd. Has been dedicated to the production and research and development of wire mesh products for 30 years. Leading Vibrating Screen It is a comprehensive department integrating production and processing, distribution and wholesale. Stainless steel mesh series, wire mesh products series, and filter elements and filter materials. Wire MeshWe can also produce various special-shaped net types and deep-processed net products according to customer needs and requirements. wire mesh suppliers All our products leaving the factory have undergone strict inspection to ensure that they are 100% qualified. Filtration Screens ManufacturerThe company adheres to the business philosophy of “technology leadership and quality victory”, and has nearly a hundred MID-to-senior level professional and technical personnel. wire mesh manufacturer We have maintained long-term and good cooperative relations with large domestic oil fields, coal mines, petroleum, machinery, chemical and other units, and have established good trade relations with more than 70 countries including the United States, Japan, Russia and Australia. Anping Tengde Metal Wire Mesh Products Co., Ltd.wire mesh screens suppliers Will continue to adhere to the tenet of “customer first, integrity-based”, and with the spirit of continuous innovation and win-win cooperation, forge ahead and challenge the future.wire mesh filter manufacturers|mesh wire suppliers