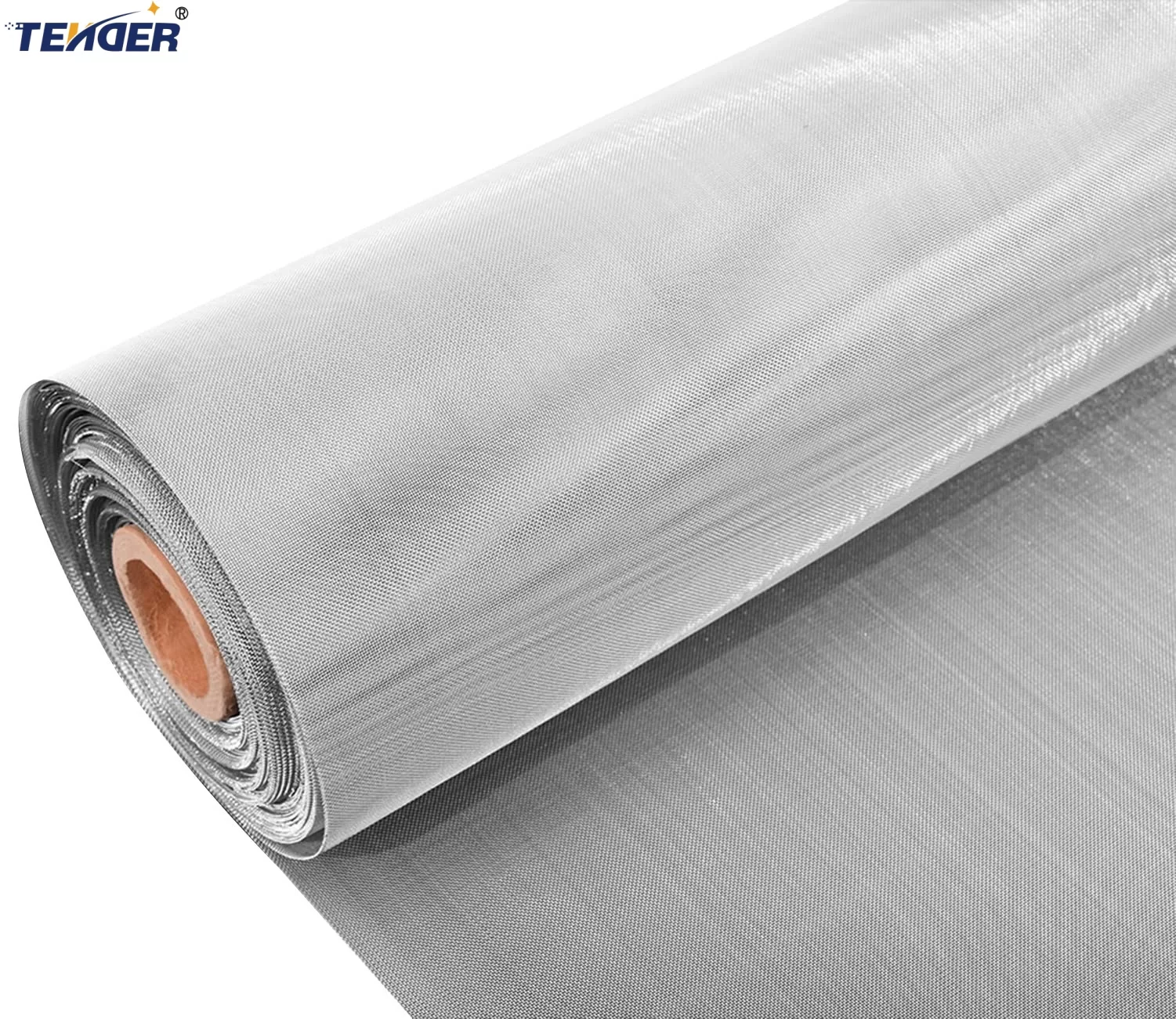

What I’m Seeing in Dutch Weaves: 904L Mesh for Tough Filtration Jobs

When engineers ask me about dutch woven wire mesh, the conversation almost always drifts to chloride stress, acid duty, and downtime math. 904L—an austenitic stainless with high Ni and Mo—keeps popping up because it hangs in there where 316L quietly gives up. Origin-wise, this one comes out of Anping, Hengshui City, Hebei, China—no surprise; that region has woven expertise in its bones.

Industry pulse

Across refineries, battery slurry plants, and desal pre-treatment, I’m seeing a tilt toward dutch woven wire mesh with tighter ratings (≤25 µm) and higher alloy content. Frankly, supply chains are tighter than they look; mills with EN 10204 3.1 traceability and bubble-point testing are getting booked out weeks in advance.

Why 904L for Dutch weaves?

904L’s Ni≈24–26% and Mo≈4.3–5% translate to a higher pitting resistance number (PREN), which is exactly what you want in chloride and acidic duty. I’ve seen it hold up in sulfuric (yes, carefully), phosphoric, and brine-rich loops where standard grades pit fast. In fact, several buyers told me their maintenance windows stretched from quarterly to annually after switching to dutch woven wire mesh in 904L.

Specs snapshot (real-world use may vary)

| Weave | Mesh (warp×weft) | Wire Ø (warp×weft) | Nominal rating | Roll width | Standard |

|---|---|---|---|---|---|

| Plain Dutch | 200×1400 | 0.07×0.05 mm | ≈25 µm | 1.0–1.5 m | ASTM E2016, ISO 9044 |

| Twill Dutch | 325×2300 | 0.035×0.025 mm | ≈15 µm | 1.0–1.2 m | ASTM E2016, ISO 9044 |

| Reverse Dutch | 400×2800 | 0.03×0.02 mm | ≈10 µm | 1.0 m | ASTM E2016, ISO 9044 |

Material: 904L SS wire per ASTM A580/A479; MTC EN 10204 3.1 available on request.

How it’s made (short version)

- Wire: 904L drawn, bright-annealed, XRF-PMI verified.

- Weaving: precision shuttle looms; Plain/Twill/Reverse Dutch depending on flow/DP targets.

- Heat treatment: stress relief where required; flattening passes for uniform caliper.

- Cleaning: ultrasonic degrease; optional passivation.

- QC: visual + caliper, mesh count, bubble-point (ASTM F316 method, where applicable), salt spray (ASTM B117), pore-size sampling.

Service life: around 1–5 years in acidic/chloride duty depending on temperature, DP cycling, and cleaning chemistry (CIP/solvent). Certifications: ISO 9001 plants are standard now; ask for RoHS/REACH if it matters to you.

Where it’s used (a few real cases)

- Refinery acids: dutch woven wire mesh cartridges in sulfuric bleed streams; DP stabilized and changeouts halved, according to one maintenance lead.

- Battery plants: NMP-based cathode slurry pre-screen; 15 µm twill dutch improved yield with fewer agglomerate defects—operator feedback was “less rework, fewer clogs.”

- Desalination: brackish water pre-filtration; 904L resisted crevice attack better than 316L at elevated chlorides.

Vendor landscape (my blunt take)

| Vendor type | Lead time | MOQ | Certs | Notes |

|---|---|---|---|---|

| Anping mill-direct (China) | 2–4 weeks | 1 roll+ | ISO 9001, EN 10204 3.1 | Best value; watch for honest tolerances and bubble-point data. |

| EU/US distributor | Stock–2 weeks | Cut lengths | ISO 9001, material trace | Fast delivery; premium pricing, reliable QA. |

| Low-cost trader | 3–6 weeks | Multiple rolls | Varies | Request PMI, E2016 conformance; specs can drift. |

Customization tips

If you’re chasing stability, ask for reverse dutch (higher throughput at the same cut) and specify post-weave leveling. Edge trimming, calendaring, and passivation make more difference than you’d think. And yes—get pore-size verification, not just a mesh count, especially for dutch woven wire mesh below 20 µm.

Citations

- ASTM E2016 – Standard Specification for Industrial Woven Wire Cloth.

- ISO 9044 – Industrial wire screening and fine mesh: Tolerances and requirements.

- ASTM B117 – Standard Practice for Operating Salt Spray (Fog) Apparatus.

- ASTM A240/A479 – Specifications for 904L (UNS N08904) stainless steel plate and bar; EN 1.4539.

Anping Tengde Metal Wire Mesh Products Co., Ltd. Has been dedicated to the production and research and development of wire mesh products for 30 years. Leading Vibrating Screen It is a comprehensive department integrating production and processing, distribution and wholesale. Stainless steel mesh series, wire mesh products series, and filter elements and filter materials. Wire MeshWe can also produce various special-shaped net types and deep-processed net products according to customer needs and requirements. wire mesh suppliers All our products leaving the factory have undergone strict inspection to ensure that they are 100% qualified. Filtration Screens ManufacturerThe company adheres to the business philosophy of “technology leadership and quality victory”, and has nearly a hundred MID-to-senior level professional and technical personnel. wire mesh manufacturer We have maintained long-term and good cooperative relations with large domestic oil fields, coal mines, petroleum, machinery, chemical and other units, and have established good trade relations with more than 70 countries including the United States, Japan, Russia and Australia. Anping Tengde Metal Wire Mesh Products Co., Ltd.wire mesh screens suppliers Will continue to adhere to the tenet of “customer first, integrity-based”, and with the spirit of continuous innovation and win-win cooperation, forge ahead and challenge the future.wire mesh filter manufacturers|mesh wire suppliers