Nickel Woven Wire Mesh: field notes from the shop floor and the lab

If you’ve ever specified Nickel woven wire mesh for corrosive media, you know the stakes. In caustic plants or battery lines, the wrong choice becomes an expensive science experiment. To be honest, I’ve learned more from operators and QC techs than from brochures—what matters is purity, weave consistency, and how it behaves after months at temperature, not just day-one shine.

What’s driving demand right now

Three big trends: decarbonization (fuel cells and hydrogen handling), electrification (battery current collectors, tabs, and thermal management), and classic chemical processing where Ni’s resistance to alkalis and neutral salts just works. Many customers say they’re moving from 316L to Nickel woven wire mesh in high-NaOH loops to cut downtime. Makes sense; real-world corrosion rates are kinder to Ni in caustic.

Origin, material, and how it’s made

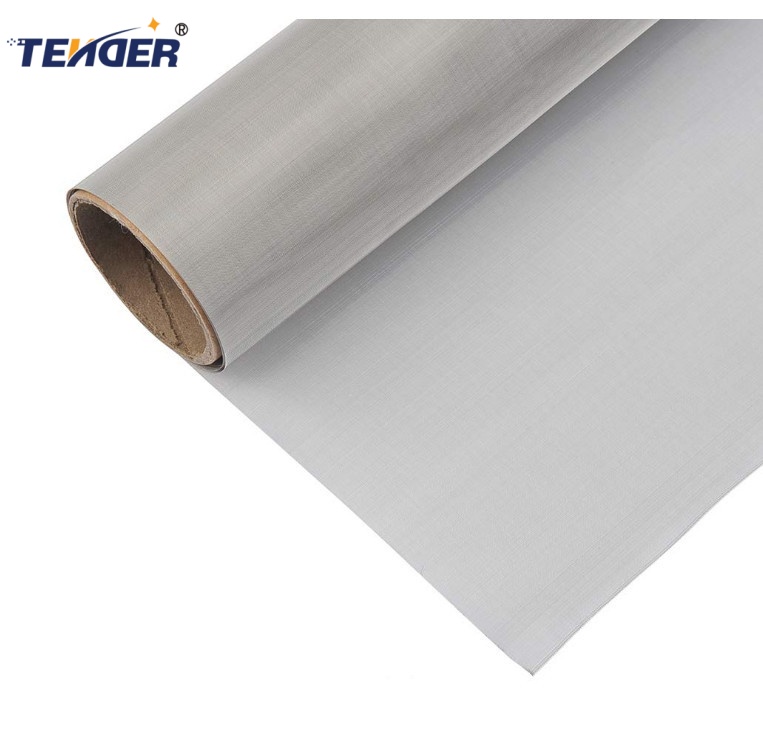

Sourced and woven in Anping, Hengshui City, Hebei, China, the mesh starts as high-purity nickel wire (≥99%, often Nickel 200/201 equivalents). Grades locally referenced as N2, N4, N6, N8 roughly map to increasing purity; you’ll see that reflected in corrosion performance and electrical conductivity. Weaving is plain or twill, chosen by mesh count and wire diameter. After weaving, it’s typically annealed for ductility, then degreased and visually inspected.

- Methods: precision warping, loom weaving (plain/twill), bright anneal, cleaning.

- Testing: wire chemistry per ASTM B160 (or mill cert), mesh tolerances to ASTM E2016 / ISO 9044, corrosion coupons by ASTM G31 (optional), conductivity spot checks.

- Service life: ≈12–36 months in strong alkali at 60–90°C (varies with concentration and flow). In neutral salt fog, longer; in oxidizing acids, shorter—verify.

Technical specifications (typical)

| Parameter | Spec (≈, real-world use may vary) |

|---|---|

| Material purity | Ni ≥ 99.0% (Nickel 200/201 equivalents on request) |

| Weave | Plain weave, Twill weave |

| Mesh counts | 2–400 mesh |

| Wire diameters | 0.020–2.0 mm |

| Width | up to 1.5 m (wider on inquiry) |

| Roll length | 10–30 m standard |

| Operating temperature | Up to ≈600°C in air; higher in inert atmospheres |

| Surface | Bright/annealed; degreased |

| Tolerances | Per ASTM E2016 / ISO 9044 |

Where it’s used (and why)

- Chemical processing: caustic filtration screens, catalysts support grids.

- Battery and energy: current collectors, busbar mesh, EMI shielding (yes, it solders nicely).

- Hydrogen and fuel cells: gas diffusion layers and porous supports (spec-driven).

- Electronics: RFI/EMI enclosures needing stable conductivity at heat.

Advantages vs stainless: superior resistance to strong alkalis, higher electrical conductivity, stable magnetism behavior (for Nickel 200/201), and predictable thermal expansion.

Vendor comparison (shortlist)

| Criteria | Anping Manufacturer (Hebei, China) | Generic Importer |

|---|---|---|

| Purity guarantee | Mill certs to ASTM B160; heat traceable | Varies; often no heat trace |

| Standards | ASTM E2016 / ISO 9044 compliance | “Commercial” tolerance |

| Lead time | 7–15 days (stock meshes) | 3–6 weeks |

| MOQ | 1 roll | Higher |

| Customization | Cut-to-size, slitting, discs, frames | Limited |

| Test reports | Corrosion and conductivity on request | Seldom provided |

Customization and QC

Options include mesh count, weave, width, anneal state, discs/strips, and framed screens. QC teams typically run mesh-count verification, diameter mic checks, flatness, and salt-spray or immersion per ASTM G31 when projects need data. One customer remarked, “Surprisingly consistent roll-to-roll; zero telescoping,” which, I guess, is the kind of dull reliability we all want.

Case notes and test data

- Alkali plant retrofit: swapping 316L for Nickel woven wire mesh (20 mesh, 0.4 mm wire) cut unscheduled maintenance by ≈35% over 14 months.

- Battery line: fine Nickel woven wire mesh at 200 mesh improved electrode coating uniformity; sheet resistance measured ≈1.2 μΩ·m equivalent path (lab panel, 25°C).

Salt-spray (neutral) exposure showed no red rust (of course) and minimal surface dulling at 240 h; immersion tests in 30% NaOH at 80°C indicated low mass loss (specific rates available on request).

Certifications and documentation

Typical deliverables: ISO 9001:2015 QMS, RoHS/REACH declarations, MTC to ASTM B160, and dimensional reports to ASTM E2016 / ISO 9044. For sour-service or hydrogen work, additional compatibility checks (e.g., per ISO 15156 environments) are advised—conditions matter.

Final thought

Specs are specs, but talk to operations. They’ll tell you how Nickel woven wire mesh behaves after a shutdown, or when the pH drifts on a Friday night. That’s the difference between a purchase and a solution.

- ASTM B160 – Standard Specification for Nickel Rod, Bar, and Wire.

- ASTM E2016/E2016M – Standard Specification for Industrial Woven Wire Cloth.

- ISO 9044 – Industrial wire screens and woven wire cloth—Technical requirements and tests.

- ASTM G31 – Standard Practice for Laboratory Immersion Corrosion Testing of Metals.

- ISO 9001:2015 – Quality management systems—Requirements.

Anping Tengde Metal Wire Mesh Products Co., Ltd. Has been dedicated to the production and research and development of wire mesh products for 30 years. Leading Vibrating Screen It is a comprehensive department integrating production and processing, distribution and wholesale. Stainless steel mesh series, wire mesh products series, and filter elements and filter materials. Wire MeshWe can also produce various special-shaped net types and deep-processed net products according to customer needs and requirements. wire mesh suppliers All our products leaving the factory have undergone strict inspection to ensure that they are 100% qualified. Filtration Screens ManufacturerThe company adheres to the business philosophy of “technology leadership and quality victory”, and has nearly a hundred MID-to-senior level professional and technical personnel. wire mesh manufacturer We have maintained long-term and good cooperative relations with large domestic oil fields, coal mines, petroleum, machinery, chemical and other units, and have established good trade relations with more than 70 countries including the United States, Japan, Russia and Australia. Anping Tengde Metal Wire Mesh Products Co., Ltd.wire mesh screens suppliers Will continue to adhere to the tenet of “customer first, integrity-based”, and with the spirit of continuous innovation and win-win cooperation, forge ahead and challenge the future.wire mesh filter manufacturers|mesh wire suppliers