What I’m Seeing in Nickel Mesh Right Now

If you’ve been anywhere near battery lines, electrolyzers, or caustic filtration lately, you’ve probably heard about

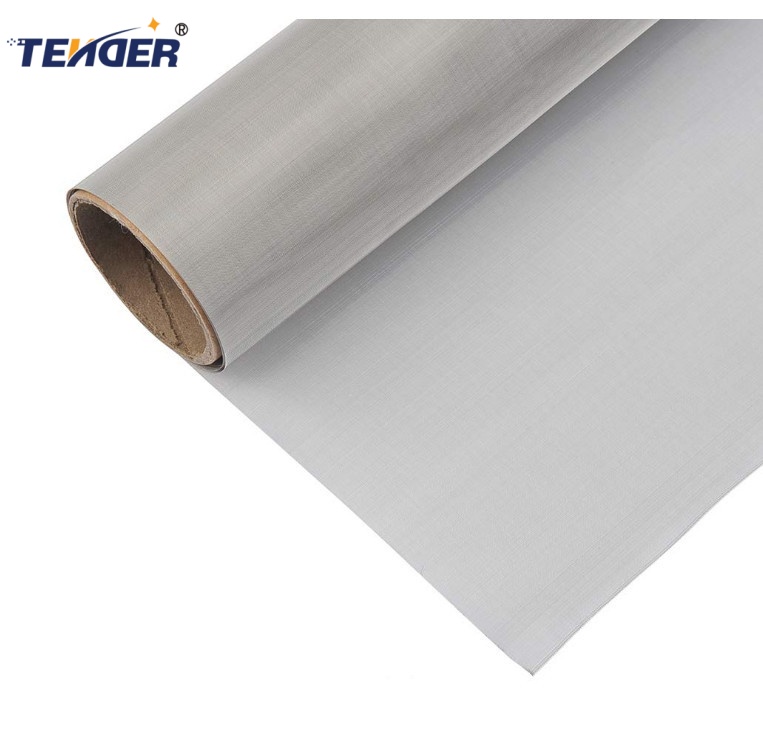

Nickel woven wire mesh. Demand is up—quietly but steadily—driven by hydrogen, chlor-alkali upgrades, and the never-ending appetite for cleaner chemistries. Nickel’s silver-white sheen is nice, sure, but what really matters is its corrosion resistance and electrical behavior. In fact, with purity ≥99% (N2/N4/N6/N8 grades), it holds up where stainless taps out.

Fast take: where it’s going

- Electrochemistry: cathodes/anodes, diaphragms, and catalyst supports (alkaline and PEM stacks).

- Battery hardware: current collectors and vent screens (yes, alkaline still matters).

- High-temp fixtures: heat-treat baskets where nickel’s creep resistance pays off.

- EMI/RF shielding: fine plain weave for stable conductivity.

Core specs (plain and twill weave)

Material: Ni ≥99.0% (typical Ni200/Ni201 chemistry; real-world use may vary). Wire is drawn, annealed, then woven—plain for stability, twill for tighter apertures.

| Mesh count (mesh/in) | Wire dia (mm) | Opening (mm) ≈ | Open area ≈ | Weave |

|---|---|---|---|---|

| 10 | 0.50 | 2.04 | ≈65% | Plain |

| 40 | 0.20 | 0.44 | ≈48% | Plain |

| 80 | 0.12 | 0.20 | ≈38% | Twill |

Nickel woven wire mesh comes in widths 0.5–1.5 m (custom on request), rolls 30 m typical, flat panels laser-cut when needed. Origin: Anping, Hengshui City, Hebei, China—still the global hub for woven metal.

How it’s made (short version)

- Materials: Ni rods to wire (ASTM B160 guidance), vacuum melt → hot/cold draw → intermediate anneal.

- Weaving: plain/twill on shuttle looms, real-time tension control; edge trimming to reduce snag.

- Cleaning: ultrasonic degrease; optional passivation for ionic cleanliness.

- Testing: mesh count per ASTM E2016, wire dia mic’ing, burr check, conductivity (σ), and corrosion coupon per ASTM G31 in NaOH.

- Packing: anti-tarnish paper, sealed PE, crated.

Performance notes

- Service life: 2–5 years in 30% NaOH at 60–80°C; 6–12 months in hot HCl (not recommended); 5+ years in alkaline batteries—your mileage will vary.

- Electrical: resistivity ≈ 0.098 μΩ·m; stable after repeated thermal cycling.

- Magnetism: weakly ferromagnetic when cold-worked; anneal if that matters for your fixture.

Vendor landscape (my quick comparison)

| Vendor | Purity | Tolerances | Lead time | Notes |

|---|---|---|---|---|

| Supplier A (EU) | ≥99.2% | Tight (ASTM E2016 Class 1) | 6–8 wks | Premium cost; great docs. |

| Supplier B (US) | ≥99.0% | Standard | 4–6 wks | Good small-batch support. |

| Anping maker (CN) | ≥99.0–99.6% | Standard to tight | 2–4 wks | Best value; flexible widths. |

Customization checklist

- Grade: Ni200 vs Ni201 (lower C for better corrosion). N4/N6/N8 when purity is critical.

- Weave: plain for strength; twill for fine openings; calendared for smoother surfaces.

- Edges: welded or selvedge; flatness spec in mm/m.

- Docs: ISO 9001, RoHS/REACH declarations, 3.1 material certs, conductivity and mesh-count reports.

Two quick case notes

Chlor-alkali retrofit: Upgrading to Nickel woven wire mesh current collectors cut cell resistance ≈7% and extended changeout intervals from 18 to 30 months (ASTM G31 test coupons predicted the same trend).

Battery line: A Tier-2 battery maker swapped perforated sheets for Nickel woven wire mesh 40 mesh; users reported steadier crimp force and fewer burr-related shorts—small win, big yield.

Final thoughts

Honestly, it’s not flashy, but Nickel woven wire mesh is one of those components that quietly de-risks your process. Source from Anping (Hengshui, Hebei) if you need cost-effective volume, and insist on test data tied to ASTM E2016 and B160. Many customers say once they dial in weave and anneal, they don’t look back.

Citations

- ASTM E2016 – Standard Specification for Industrial Woven Wire Cloth.

- ASTM B160 – Standard Specification for Nickel Rod and Bar.

- ASTM G31 – Standard Practice for Laboratory Immersion Corrosion Testing of Metals.

- UNS N02200/N02201 (Nickel 200/201) composition and properties, SAE/ASM datasheets.

- ISO 9001:2015 – Quality management systems requirements.

Anping Tengde Metal Wire Mesh Products Co., Ltd. Has been dedicated to the production and research and development of wire mesh products for 30 years. Leading Vibrating Screen It is a comprehensive department integrating production and processing, distribution and wholesale. Stainless steel mesh series, wire mesh products series, and filter elements and filter materials. Wire MeshWe can also produce various special-shaped net types and deep-processed net products according to customer needs and requirements. wire mesh suppliers All our products leaving the factory have undergone strict inspection to ensure that they are 100% qualified. Filtration Screens ManufacturerThe company adheres to the business philosophy of “technology leadership and quality victory”, and has nearly a hundred MID-to-senior level professional and technical personnel. wire mesh manufacturer We have maintained long-term and good cooperative relations with large domestic oil fields, coal mines, petroleum, machinery, chemical and other units, and have established good trade relations with more than 70 countries including the United States, Japan, Russia and Australia. Anping Tengde Metal Wire Mesh Products Co., Ltd.wire mesh screens suppliers Will continue to adhere to the tenet of “customer first, integrity-based”, and with the spirit of continuous innovation and win-win cooperation, forge ahead and challenge the future.wire mesh filter manufacturers|mesh wire suppliers