In industrial filtration, efficiency and durability are paramount. Discover how our Wedge Wire Filter Panel excels in demanding environments.

What is a Wedge Wire Filter Panel?

A Wedge Wire Filter Panel, also known as a profile wire screen or V-wire screen, is a filter plate structure made by welding V-shaped (wedge-shaped) metal wires and support rods (usually trapezoidal or rectangular). This robust construction is commonly used in solid-liquid separation, screening, dehydration, and filtration systems across various industries. Its unique wedge-shaped structure gives it continuous gaps, a non-clogging design, high strength, and excellent corrosion resistance.

These panels are widely applied in sectors such as water treatment, papermaking, food & beverage, mining, chemical processing, and petroleum. Their precision engineering ensures efficient separation and long service life, making them a preferred choice for critical industrial applications. When you're looking for a reliable wedge wire screen for sale, our panels represent the pinnacle of quality and performance.

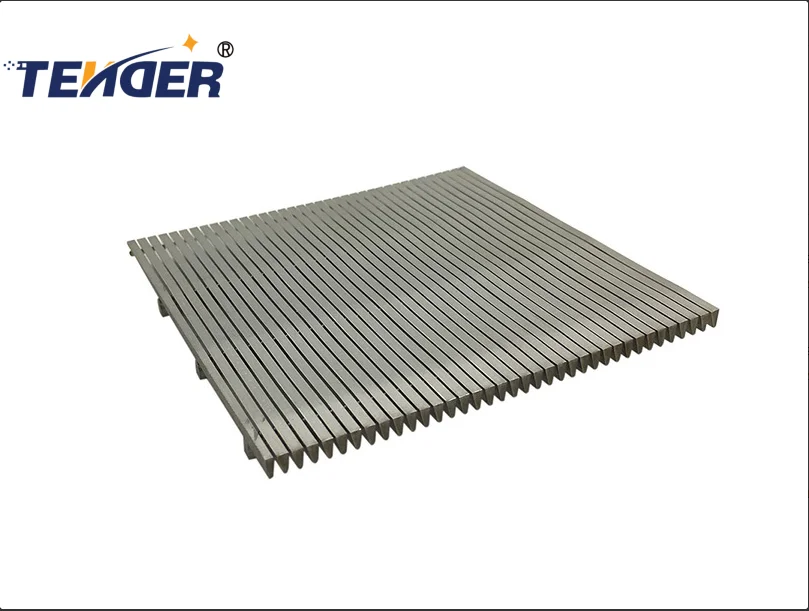

Precision-engineered Wedge Wire Filter Panel for optimal separation.

Key Features & Advantages of Our Wedge Wire Filter Panels

· Non-Clogging Design: The V-shaped wire profile creates a "point contact" with particles, minimizing clogging and maximizing flow rates. This makes them an excellent self cleaning wedge wire screen solution.

· High Open Area: Offers a larger open area compared to traditional screens, leading to increased throughput and reduced pressure drop.

· Superior Strength & Durability: Fusion-welded construction from high-quality materials, often stainless steel wedge wire screen, ensures exceptional mechanical strength and resistance to deformation.

· Corrosion & Abrasion Resistance: Typically manufactured from various grades of stainless steel (e.g., 304, 316L), providing excellent resistance to corrosive chemicals and abrasive slurries.

· Precise Slot Sizes: Consistent and accurate slot openings for fine, efficient separation and filtration, crucial for applications requiring exact particle retention.

· Low Maintenance: The self-cleaning nature and robust construction significantly reduce maintenance requirements and downtime.

· Versatile Applications: Suitable for a wide range of uses, from dewatering to sizing, often replacing traditional mesh or perforated plates with superior performance.

Detailed Product Specifications: Wedge Wire Filter Panel

|

Parameter |

Specification |

Typical Range/Notes |

|

Material |

Stainless Steel (304, 304L, 316, 316L) |

Other alloys available upon request |

|

Wire Profile (Wedge Wire) |

V-shaped, Triangular |

Standard widths: 1.5mm to 3.0mm |

|

Support Rod Profile |

Trapezoidal, Rectangular |

Standard sizes: 2x3mm, 3x5mm, 4x6mm |

|

Slot Opening |

0.025 mm (25 microns) to 10 mm |

Customizable to application requirements |

|

Panel Dimensions |

Length up to 6 meters, Width up to 3 meters |

Custom sizes available |

|

Surface Treatment |

Pickling, Passivation, Electro-polishing |

Enhances corrosion resistance and cleanliness |

|

Filtering Direction |

Inside-out, Outside-in |

Depends on panel configuration and application |

|

Operating Temperature |

Up to 200°C (depending on material) |

Specific limits per alloy |

|

Pressure Rating |

Designed to withstand process pressures |

Calculated based on panel design and support structure |

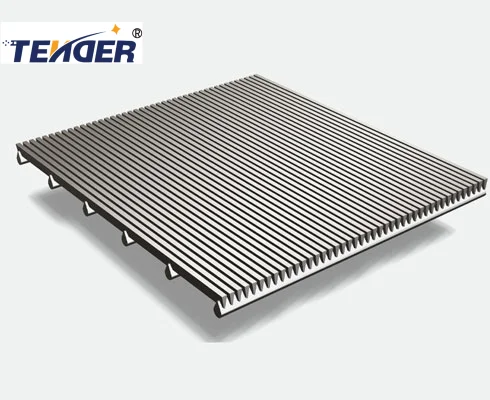

Close-up view of the robust construction of a Wedge Wire Filter Panel.

Manufacturing Process: Quality from the Ground Up

Our Wedge Wire Filter Panel manufacturing process follows stringent quality control to ensure superior product performance and longevity.

1. Material Selection: We primarily use high-grade stainless steel wedge wire screen materials (SS304, SS316, SS316L) sourced from certified suppliers, meeting ASTM standards for chemical composition and mechanical properties. This ensures corrosion resistance and mechanical strength.

2. Wire Shaping & Preparation: Precision machinery forms the V-shaped profile wires and trapezoidal/rectangular support rods. The wires are checked for uniformity and surface finish.

3. Automated Welding: Using advanced resistance welding or plasma welding techniques, the V-shaped wires are continuously welded to the support rods at precise intervals. This creates a strong, unitary panel with consistent slot openings. Our methods conform to AWS D1.6 (Structural Welding Code – Stainless Steel).

4. Cutting & Shaping: Panels are cut to specified dimensions, and further shaping (e.g., bending, rolling) is performed as per custom designs for applications like sieve bend screen or cylindrical filters.

5. Surface Treatment: Post-welding, panels undergo pickling and passivation to remove welding discoloration, enhance corrosion resistance, and achieve a clean, smooth surface. Electro-polishing is available for specialized applications requiring ultra-clean surfaces.

6. Quality Inspection & Testing: Each profile wire screen undergoes rigorous inspection. This includes visual checks for defects, dimensional accuracy (length, width, flatness), and precise slot opening measurement using digital calipers and optical comparators. Burst pressure tests and flow rate performance tests are conducted on samples to validate structural integrity and filtration efficiency, adhering to ISO 9001 quality management standards.

7. Packaging: Finished panels are carefully packaged to prevent damage during transit, often using wooden crates or pallets with protective wrapping.

Service Life: With proper maintenance and material selection, our Wedge Wire Filter Panel products can achieve a service life of 5-15 years or more, significantly outperforming conventional screen types.

Applicable Industries: Water Treatment, Pulp & Paper, Mining & Aggregates, Food & Beverage, Petrochemical, Chemical Processing, Waste Management, Brewing, Starch Production, and many more.

Applications & Usage Scenarios

The versatility of the Wedge Wire Filter Panel makes it indispensable across numerous industries for a variety of tasks:

§ Water Treatment: Used in intake screens, dewatering systems, clarifiers, and as underdrain media retention for ion exchange and sand filters. Ideal for applications requiring robust static wedge wire screens.

§ Pulp & Paper: For fiber recovery, dewatering, and screening processes, improving efficiency and reducing downtime.

§ Mining & Aggregates: In sizing, dewatering, and washing operations for minerals, coal, sand, and gravel. Sieve bend screen designs are particularly effective here.

§ Food & Beverage: For juice extraction, sugar refining, brewing, and starch separation, where hygiene and precise filtration are critical. Our stainless steel wedge wire screen ensures food-grade compliance.

§ Petrochemical & Chemical: As support grids in reactors, catalyst retention, and liquid-solid separation in corrosive environments.

§ Waste Management: For municipal and industrial wastewater screening and sludge dewatering.

§ Architectural & Decorative: Due to their clean lines and strength, they are sometimes used for architectural facades, sunscreens, and decorative elements.

Whether it's a fixed panel in a dewatering trough or a component in a vibratory screen, the V wire screen construction consistently delivers superior performance.

Customization Options

We understand that every industrial application has unique requirements. Our Wedge Wire Filter Panel products are highly customizable to perfectly match your operational needs:

o Material: Stainless steel grades (304, 304L, 316, 316L, 321, 904L, Duplex), Hastelloy, Inconel, Monel, etc.

o Slot Size (Aperture): From 0.025 mm up to 10 mm, with precise control.

o Wire & Support Rod Dimensions: Various V-wire sizes and support rod profiles to optimize strength and open area.

o Panel Dimensions: Custom length, width, and thickness to fit existing infrastructure or new designs.

o Frame & Edge Reinforcement: Panels can be supplied with custom frames, flanges, or reinforced edges for structural integrity and ease of installation.

o Surface Finish: Standard pickled and passivated, or electro-polished for enhanced hygiene and corrosion resistance.

o Configuration: Flat panels, curved panels, cylinders, cones, and customized shapes for specialized equipment like sieve bend screen units.

Our engineering team works closely with clients to design solutions that deliver optimal performance for their specific challenges.

Real-World Case Studies

· »Mining Dewatering Project: A large copper mine replaced traditional perforated plates in their dewatering sumps with our custom-designed Wedge Wire Filter Panel. This resulted in a 30% increase in dewatering efficiency, a 50% reduction in screen blinding, and extended screen lifespan by 3 years, significantly cutting maintenance costs.

· »Food Processing Waste Stream: A major poultry processing plant implemented our self cleaning wedge wire screen panels for fat and solids separation from their wastewater. The non-clogging nature minimized manual cleaning, leading to a 40% reduction in labor for screen maintenance and improved compliance with discharge regulations.

· »Municipal Water Intake: For a coastal municipal water treatment plant, we supplied large V wire screen intake panels to prevent marine debris and aquatic life from entering the system. The robust stainless steel construction and precise slot sizes ensured reliable performance and ecological protection even in harsh saltwater conditions.

Certifications & Quality Assurance

Our commitment to quality is upheld by adherence to international standards and rigorous testing. We ensure every Wedge Wire Filter Panel meets or exceeds industry expectations.

· ✓ISO 9001:2015 Certified:Our manufacturing processes are certified under ISO 9001, demonstrating our robust Quality Management System.

· ✓Material Certifications:All raw materials, especially ourstainless steel wedge wire screen, come with Mill Test Certificates (MTCs) confirming chemical composition and mechanical properties per ASTM A240/A276.

· ✓Precision Slot Testing:We utilize advanced optical measurement tools to ensure slot opening accuracy within industry-leading tolerances.

· ✓Hydrostatic & Flow Testing:Sample panels undergo hydrostatic pressure tests and flow rate performance tests to guarantee structural integrity and filtration efficiency under operating conditions.

· ✓Welding Standards:Our welding procedures adhere to recognized standards like AWS D1.6 for stainless steel welding.

We maintain detailed test data and inspection reports for every batch, available upon request.

Why Choose Us? Vendor Comparison

When selecting a supplier for your Wedge Wire Filter Panel needs, the choice can significantly impact your operational efficiency and long-term costs. Here's how we stand out:

|

Feature/Service |

Our Offering |

Typical Competitor |

|

Customization Capability |

Extensive (any size, slot, material, frame) |

Limited (standard sizes only) |

|

Material Quality (Stainless Steel) |

Certified MTCs, Premium Grades (SS316L+) |

Basic grades, inconsistent sourcing |

|

Welding Precision |

Automated, consistent slot accuracy (ISO & AWS standards) |

Manual variations, less uniform slots |

|

Engineering Support |

Dedicated team for design & application advice |

Basic sales support only |

|

Lead Time for Custom Orders |

Efficient, often faster than industry average |

Longer lead times due to limited capacity |

|

After-Sales Support & Warranty |

Comprehensive warranty, responsive issue resolution |

Limited or no specific warranty |

The structural integrity of our Wedge Wire Filter Panel ensures reliable performance.

Customer Testimonials

"The Wedge Wire Filter Panel from [Manufacturer Name] significantly improved our dewatering process. The self-cleaning aspect has cut our maintenance time by half. Truly a game-changer!"

— Operations Manager, Chemical Plant

"We needed custom sieve bend screen panels for a unique application, and this team delivered perfectly. The quality of the stainless steel wedge wire screen was exceptional, and their technical support was invaluable."

— Project Engineer, Food & Beverage Industry

Frequently Asked Questions (FAQ)

Q: What is the typical lead time for a custom Wedge Wire Filter Panel order?

A: Lead times vary based on complexity, material availability, and order size. Generally, custom orders are completed within 3-6 weeks from design approval. Standard panels may be available sooner.

Q: How do I determine the correct slot size for my application?

A: This depends on the particle size you need to retain and the required flow rate. Our engineering team can assist you in selecting the optimal slot size based on your process parameters and material characteristics.

Q: Can these panels be used in high-temperature or corrosive environments?

A: Yes, by selecting appropriate materials like SS316L, Hastelloy, or Duplex stainless steel, our profile wire screen panels are highly resistant to both high temperatures and corrosive media.

Q: Is installation complicated?

A: Our panels are designed for straightforward installation. We can provide guidance and, for complex systems, advise on best practices or custom framing options to ease integration.

Ordering & Support

Delivery Time: Standard orders for existing designs can often be fulfilled within 2-4 weeks. Custom fabrication typically requires 4-8 weeks, depending on design complexity and material availability. Expedited options may be available upon request.

·

Warranty: We offer a comprehensive 12-month warranty on our Wedge Wire Filter Panel products against manufacturing defects and material failures under normal operating conditions. Extended warranties are available for specific projects.

·

After-Sales Support: Our dedicated technical support team is available to assist with installation guidance, troubleshooting, and performance optimization. We are committed to ensuring your continued satisfaction and the peak performance of our V wire screen solutions.

Ready to enhance your filtration processes? Contact us today for a consultation or quote on our premium Wedge Wire Filter Panel solutions.

References

1. ASTM International. (2023). ASTM A240/A240M, Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications.

2. American Welding Society. (2017). AWS D1.6/D1.6M:2017, Structural Welding Code – Stainless Steel.

3. International Organization for Standardization. (2015). ISO 9001:2015, Quality management systems – Requirements.

4. Industrial Filtration & Separation Magazine. (2022). "Advances in Wedge Wire Technology for Enhanced Industrial Processing." Vol. 18, Issue 3, pp. 45-52.

5. Journal of Water Process Engineering. (2021). "Optimizing Water Intake Screens with V-Wire Profiles for Marine Environment." Vol. 40, 101732.

Anping Tengde Metal Wire Mesh Products Co., Ltd. Has been dedicated to the production and research and development of wire mesh products for 30 years. Leading Vibrating Screen It is a comprehensive department integrating production and processing, distribution and wholesale. Stainless steel mesh series, wire mesh products series, and filter elements and filter materials. Wire MeshWe can also produce various special-shaped net types and deep-processed net products according to customer needs and requirements. wire mesh suppliers All our products leaving the factory have undergone strict inspection to ensure that they are 100% qualified. Filtration Screens ManufacturerThe company adheres to the business philosophy of “technology leadership and quality victory”, and has nearly a hundred MID-to-senior level professional and technical personnel. wire mesh manufacturer We have maintained long-term and good cooperative relations with large domestic oil fields, coal mines, petroleum, machinery, chemical and other units, and have established good trade relations with more than 70 countries including the United States, Japan, Russia and Australia. Anping Tengde Metal Wire Mesh Products Co., Ltd.wire mesh screens suppliers Will continue to adhere to the tenet of “customer first, integrity-based”, and with the spirit of continuous innovation and win-win cooperation, forge ahead and challenge the future.wire mesh filter manufacturers|mesh wire suppliers